Quality

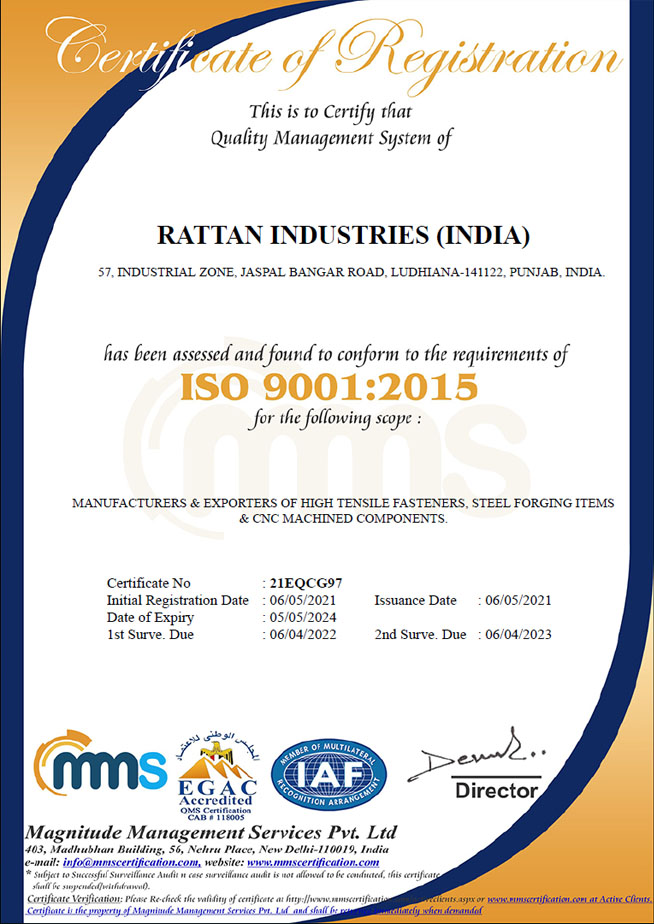

Quality Certification

Rattan Industries (India) is and ISO 9001:2015 certified company. Quality has been a area of core significance to our entire precision fasteners manufacturing and hot forging products operations. Our each manufacturing operations from sourcing of raw materials to the production, packaging and shipping, we ensure the highest standards of quality at all stages. Our quality management system ensures that our clients are provided with products that meet their expectations in terms of quality and performance.

Quality Policy

Rattan Industries (India) are committed to meet customer's expectation through continual improvements in all our various fasteners manufacturing processes and committed to improve our customer satisfaction level through supplying of quality products.

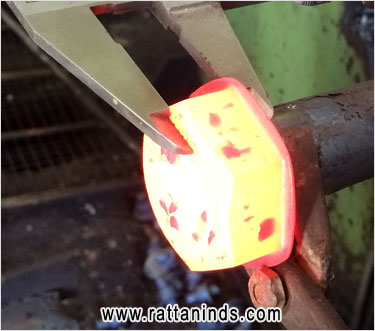

Research & Development

Innovation and improvement of existing forged products is initiated on regular basis at Rattan Industries (India). We have facilities like heat treatment, normalizing furnaces, hardnesss testing, chemical and physical testing laboratories. Our such capabilities provides innovative high tensile fasteners products to customers on a consistent basis and cater to their most demanding custom requirements

Raw Material Testing

We procure tested raw material from leading manufacturers and stockist or even import in the form of rolled billets, rounds and slabs. The raw material is tested for chemical composition , physical properties and ultrasonic test as may be necessary in house and Govt approved test house as per customer requirement.

- Ultrasonic Testing of Each Length

- Chemical Composition

- Step Down Testing

- Hardness Testing

- Grain Flow Testing